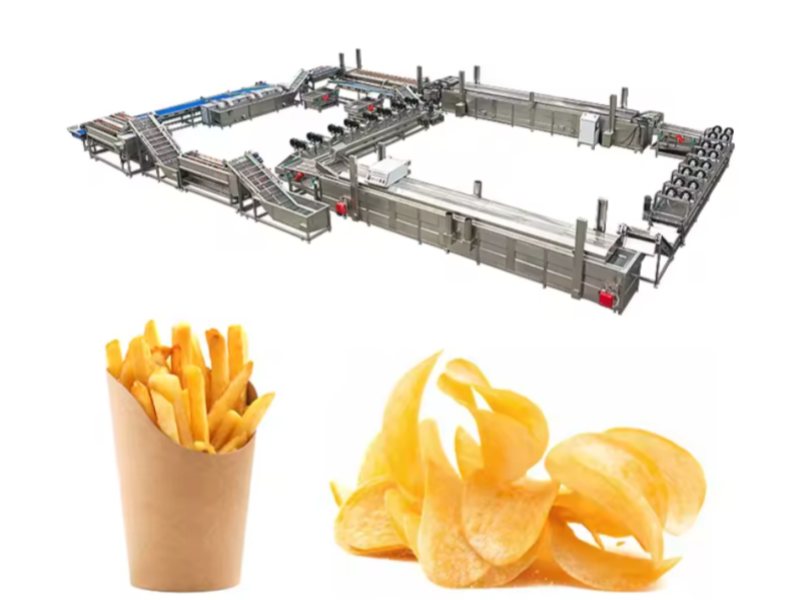

From potatoes to golden and crispy French fries, what kind of delicious journey has it gone through? Potatoes grow underground, and cleaning is particularly important for the food hygiene of French fries. The brush cleaning machine can remove the potato skin while thoroughly cleaning the potatoes; the peeled potatoes are cut into potato strips of uniform specifications by the multi-functional vegetable cutter; the potato strips are rich in starch and are easy to change color when exposed to air. The blanching in the blanching machine plays a role in color protection; the air knife air dryer can blow away the moisture on the surface of the potato strips; frying is the key to the entire French fries production. The fully automatic constant temperature control of the continuous fryer makes the fried French fries golden in color and crispy in taste; after de-oiling by the vibration oil drainer and cooling by the air dryer; the quick freezing technology is the core of the entire quick-frozen French fries production line. Through the quick freezing of the quick freezer, the French fries can be brought to supermarkets through the cold chain and into thousands of households. Clink this link to find more types of French fries line.

Fully Automatic French Fries Line VS. Semi-Automatic French Fries Line

1. Greater output

The machine of the fully automatic French fries production line works closely together, and the processing efficiency is rapidly improved. In just ten minutes, you can see that a batch of potatoes have been processed into French fries, and only the quick freezing process remains.

2. Less labor

The fully automatic French fries production line only requires a small amount of labor and technical engineers. You only need to observe the orderly connection of each device and pre-set the blanching, frying and quick freezing time.

3. Safe food quality

For semi-automatic production lines, some processes are still completed manually. Human participation will lead to some uncontrollable factors, which will affect food hygiene and safety. The fully automatic production line can avoid the above situation.

4. More investment

For production lines with the same output, the investment in fully automatic production lines is relatively large. However, after a period of operation, the saved labor wages and increased production income can effectively make up for the extra investment.

Whether to choose a fully automatic French fries production line or a semi-automatic French fries production line mainly depends on investment planning and business expectations. However, whether it is fully automatic or semi-automatic, our company can propose targeted processing solutions according to your processing needs.